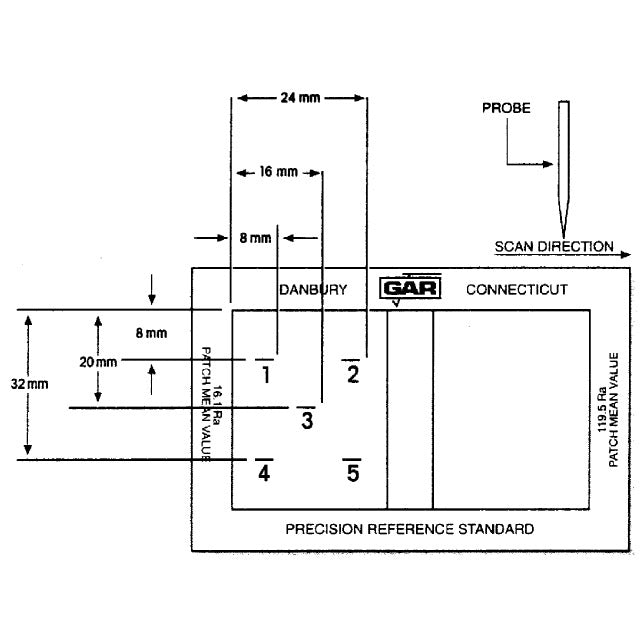

Precision Reference Standard and Stylus Check

Description

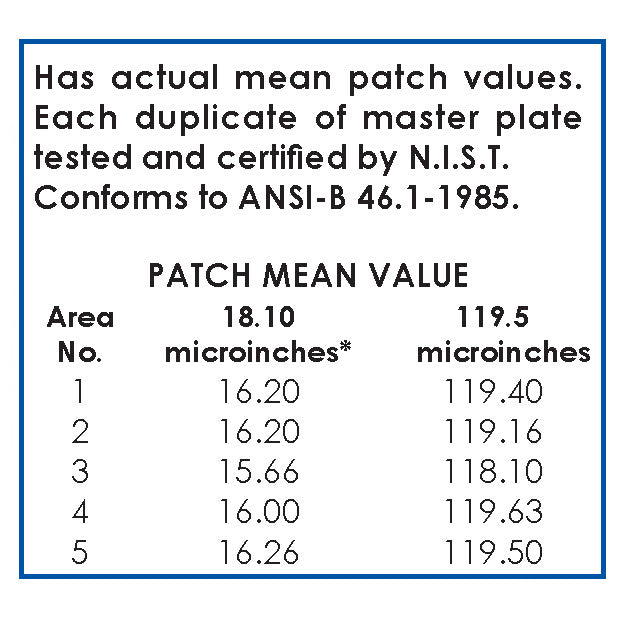

Shows actual patch mean values certified by the National Institute of Standards and Technology (NIST).

Calibrate your surface analyzing equipment to peak efficiency.

The Precision Reference Standard provides an economical calibration tool which permits the technician to calibrate surface analyzing equipment to its peak efficiency. It is the only calibration block on the market to show the actual patch mean values of low and high microinch surfaces and certified by N.I.S.T.

The surface of the Precision Reference Standard consists of a series of parallel, uniform, "V-shaped" grooves having an included angle of 150° between the sides. Since the surface character of the Precision Reference Standard is unlike normally machined surfaces, it is not recommended for use in visual or tactual comparison.

Report of Calibration by N.I.S.T.

The property of surface roughness in the 125 microinch range and below is maintained by N.I.S.T. by means of master roughness specimens conforming to ANSI-B 46.1. The master specimens were calibrated by measuring their surface profile with a stylus instrument which in turn was calibrated by an interferometrically measured step. The areas under the profile curves were then measured and the roughness average computed. The accuracy of this measurement is 2% for the 119.5 and 1 microinch for the 16.1.

Specifications

Dimensions: 2 1/2" x 3 3/4"

Has actual mean patch values. Each duplicate of master plate tested and certified by N.I.S.T. Conforms to ANSI-B 46.1-1985.

Set No. 16037, Made of pure electroformed nickel. Provided with protective case.